Read more of the latest news from Nabtesco. Discover our company news, specialist articles, press releases and LinkedIn Posts.

There are numerous areas where car manufacturers and suppliers can boost efficiency in the production of electric vehicles. Underestimated in the past, although decisive is the choice of gear technology. Gearboxes are a central element in the drive train of production machinery and play a central part in the performance of machines and systems. They transmit and convert torques, speeds and directions of rotation, as well as forces, and therefore define the production cycle. If gearboxes do not operate with the required precision, speed and reliability, this will affect the performance of the machine or system accordingly. That makes gears a key element for production efficiency.

Cycloidal gears enable fast and precise positioning of high loads with virtually no backlash to guarantee pin-point placing and positioning of assemblies, components, workpieces and tools. The special design of cycloidal gears makes them much more precise, dynamic and rigid than the commonly used rotary indexers, worm gears and planetary gears – which makes it possible to improve efficiency substantially. For example, they can reduce the time needed for single process steps by up to 40 percent.

Cycloidal gears use cams and rollers for power transmission. This ensures high efficiency, a long life and extremely low backlash, with a hysteresis loss between 0.5 and 1 arcmin, at the most. In addition, their special design achieves excellent behaviour with respect to dynamics, load capacity and smooth operation. The gears perform flawlessly even in high-precision positioning applications with heavy loads or very fast and abrupt motions. The integrated angular ball bearings absorb both axial and radial loads and bending moments, and provide for high torsional rigidity and resistance to impacts and overloading (up to 500 % of the rated torque). In addition, the lightweight design ensures applications with lower inertia, improved load conditions and reduced power consumption.

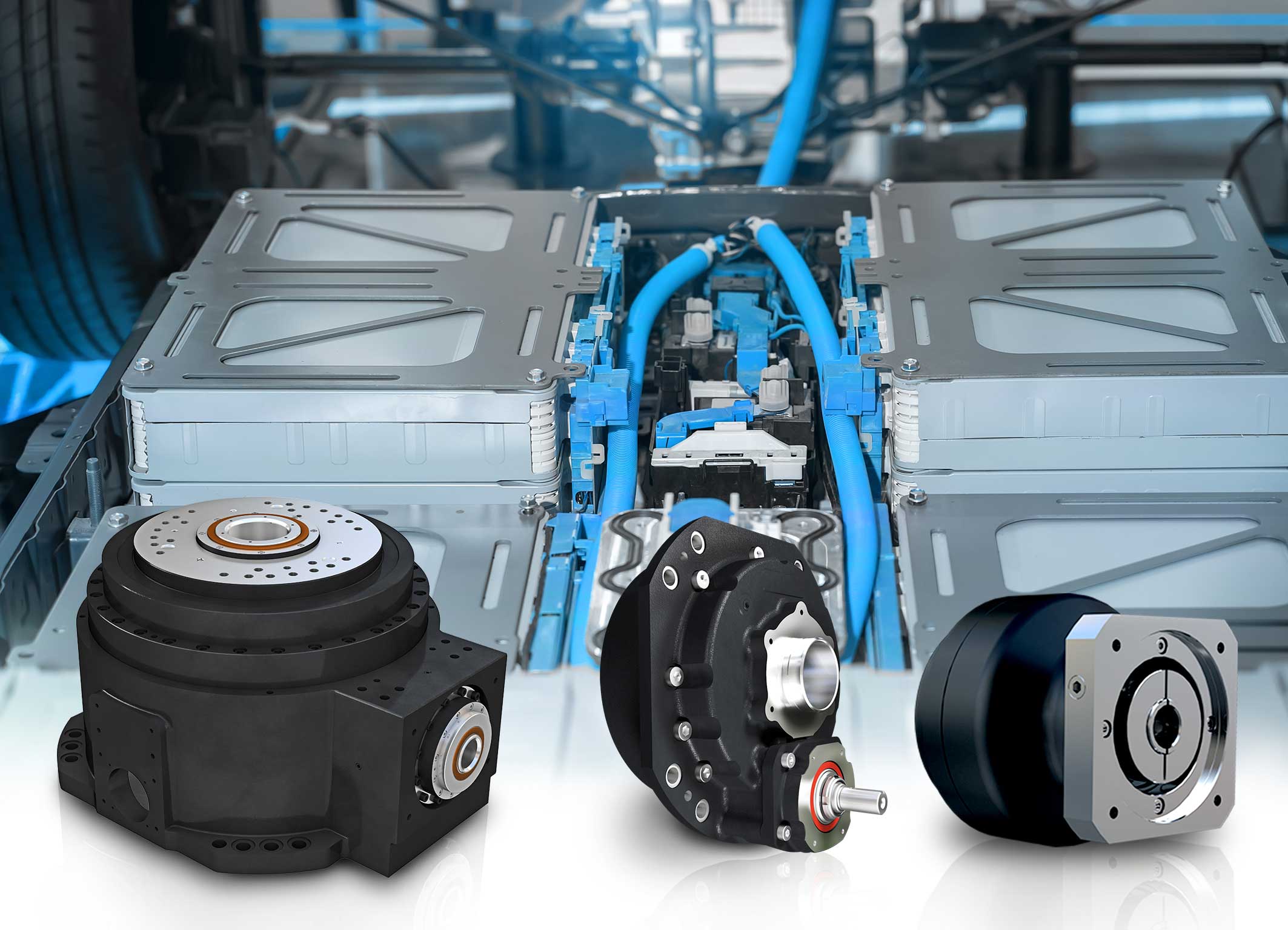

Whether in battery production, electric motor manufacturing or body construction: As the world’s biggest manufacturer of cycloidal gears, Nabtesco offers a broad portfolio of precision gears with hollow and solid shafts and provides flexible, high-performance, future viable drive solutions for electric vehicles. For the automation of peripheral handling and positioning tasks, the servo gearboxes of the Neco®, RD-C and RS series have proven themselves many times over. The use of Nabtesco gears is a guarantee for maximum precision, optimal product quality and stable processes. User convenience, flexibility and cost-effectiveness are at the focus.

For more information, read the white paper “Cycloidal gears for eMobility”. Free download here.