Read more of the latest news from Nabtesco. Discover our company news, specialist articles, press releases and LinkedIn Posts.

Different applications, industries and areas of application have different requirements for gear solutions. The field of robotics, for example, requires highly integrable component sets that ensure maximum flexibility as well as a high level of economic efficiency in large-scale production. General mechanical engineering on the other hand requires highly user-friendly solutions that involve minimal engineering and installation effort. In choosing the gear solution, the focus is therefore on aspects such as the type of application (e.g. pick and place, handling or workpiece positioning), the number of gearboxes needed or the desired level of integration expense. Other factors include the relevant specifications for precision, dynamics and payload, as well as the available installation space and cable routing requirements.

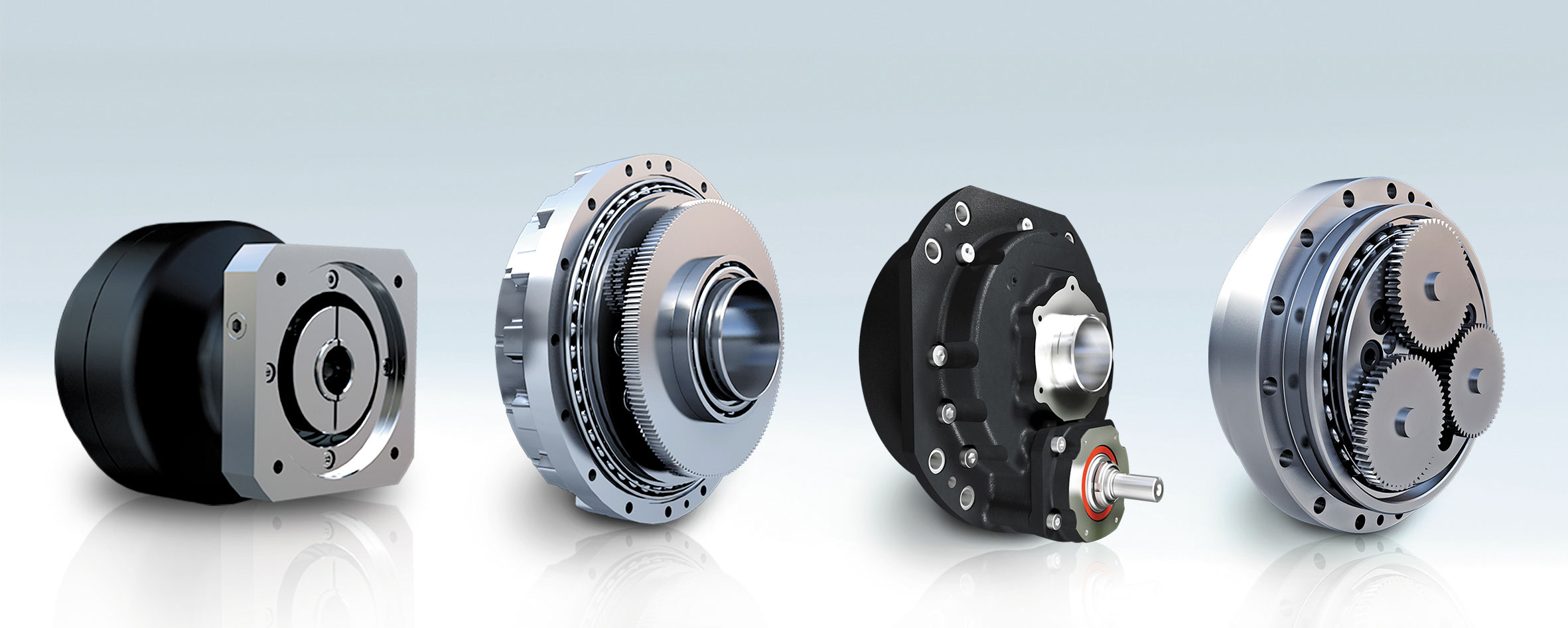

Meanwhile, more than nine million precision gearboxes from Nabtesco are in use around the world. With their outstanding precision and dynamic properties they guarantee fast processing, high product quality and maximum efficiency. For the construction of robots, the compression sets of the RV-N (solid shaft) and RV-C (hollow shaft) series have withstood the test of time. They were specially developed for robotics and are perfectly adapted to the requirements of the industry. They are built for virtually zero backlash power transmission with maximum rigidity and precision, high acceleration torques, high shock resistance up to 500 % of the rated torque, and extremely low backlash of less than one arcminute. Six of ten industrial robots contain solutions provided by Nabtesco. That makes the gear specialist with European headquarters in Düsseldorf the undisputed market leader in robotics.

The modular gearboxes of the Neco® series from Nabtesco now also make the robot technology available for classic mechanical engineering. The ready-to-install servo gearboxes achieve high precision with a hysteresis loss of 0.5 arc.min and feature an extremely robust design with double-bearing eccentric shafts and a bearing-mounted drive shaft. Motor shaft adaptation is achieved by means of a radial locking ring in a low-inertia version. This reduces the inertia of the motor shaft by up to 39 percent to enable extremely dynamic cycles. A unique aspect is the focus on usability: Neco® gears are designed for user-friendly and intuitive selection, configuration, installation and utilisation. This allows even small and mid-sized enterprises to automate their processes without prohibitive expense and without the need for special expert knowledge.

If an application requires an especially lightweight design or the routing of cables and hoses, the hollow shaft gearboxes of the RD-C series are an ideal choice. The hollow space inside substantially reduces the weight while providing a space-saving solution for routing data and power cables, as well as drive shafts, through the middle of the gearbox. Another advantage is that the hollow shaft does not remain rigid, but rather is designed to rotate at the output rpm. This makes it possible to determine the position of the drive shaft directly by means of a sensor on the hollow shaft.

Whatever the requirements: With the company’s extensive portfolio, high level of engineering expertise and many years of application experience, Nabtesco delivers efficient automation solutions for every specific application. The precision gears guarantee precisely executed motions and pinpoint positioning – also in the event of high acceleration torques and heavy loads, or in hygiene-critical environments. A special design using cams and rollers greatly minimises wear. Cycloidal gears require no readjustment, since they maintain their minimal backlash throughout the entire service life. Maximum precision and reliability, as well as a long life, are therefore guaranteed.