OVALO

Strain wave gears

Backlash-free, specific and efficient

Strain wave gears of the brand OVALO, a 100 percent subsidiary of Nabtesco Corporation, are an ideal supplement to the Nabtesco portfolio. They feature zero backlash, excellent repeat accuracy and high torque capacity – all in a compact and lightweight design. These small precision gears are ideal for use in low-torque applications that require high performance in a small space.

Precision gears in large-batches

OVALO GmbH, a subsidiary of Nabtesco Corporation, specialises in mechatronic drive systems for use in large-scale production applications. The company’s core competences include the development and production of zero backlash strain wave gears with high reduction ratios. OVALO was the first company to achieve efficient large-scale production of strain wave gears.

- Zero backlash strain wave gears of excellent quality

- Small precision gears for cobots

- Custom tailored in large-scale production

- Successfully used in automotive applications

- Maximum cost effectiveness

- Consistent customer orientation

Custom strain wave gears

OVALO specialises in custom designed gears. All strain wave gears are designed and developed to exact customer requirements and expectations. In close cooperation with the customer, the result is a highly efficient and economical drive solution that is 100 % custom tailored to the specific application. The motto: Instead of adapting the application to the gear, the gear is adapted to the requirements.

- Custom designed strain wave gears

- Drive solutions that are exactly designed for the application

- 100 % custom-tailored for performance, size and interfaces

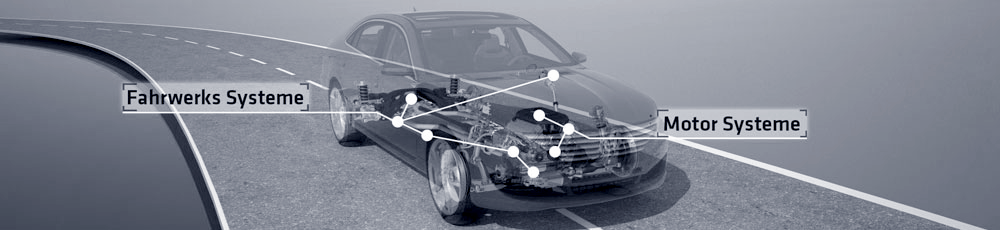

Precision gears manufactured according to automotive standards

OVALO has an in-house engineering and motor development department, modern prototyping with close-to-production quality, and a test centre for conducting mechanical and climatic tests of specifically developed systems. All production and assembly processes are carried out using state-of-the-art systems. All processes are designed to automotive standards and are IATF certified, the most important international standard for quality management in the automotive industry.

Automotive-compliant production:

- Highest level of quality

- Large quantities

- Automated production processes

- High process reliability and full traceability

- High efficiency level

- Short development cycles

Strain wave gear technology

Strain wave gears consist of three elements: the ring gear (a cylindrical ring with internal gearing), the flexible ring (a cylindrical, flexible steel bush with external gearing), and the wave generator (an elliptical steel disc with a centric hub and a special elliptical, flexible special ball bearing).

The elliptical wave generator deforms the flexible ring by means of the ball bearing. The flexible ring engages with the internal gearing of the ring gear in the opposite zones of the major elliptical axis. The rotary movement of the wave generator displaces the major elliptical axis and therefore the zone where the gear teeth engage. Since the flexible ring has two fewer teeth than the hollow ring, half a revolution of the wave generator results in a relative movement of one tooth between the flexible ring and the hollow ring, and of two teeth after a full revolution.

Benefits of product:

- Zero backlash

- Excellent transmission accuracy and repeatability

- Compact dimensions and low weight

- High torque capacity

- High reduction ratios within a transmission stage

- High efficiency

- High torsional rigidity

- Option for central hollow shaft

- High reliability and long life