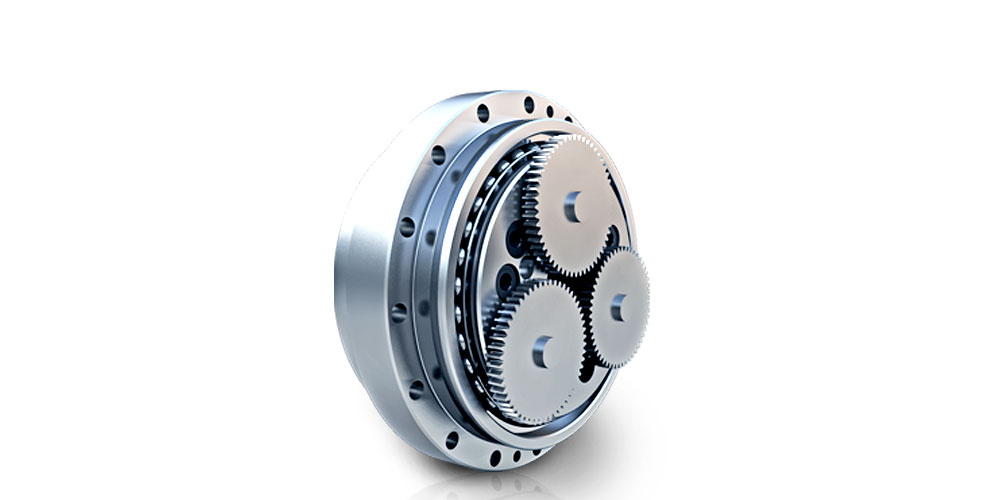

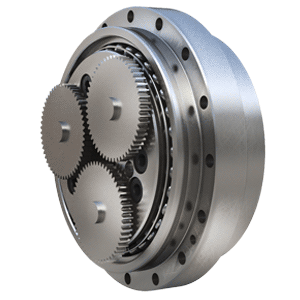

We developed the component sets of the RV-N series as very compact, lightweight and high-performance solid shaft gears. These gears are used in applications with limited space that require high torque performance. Perfect for robotics!

High shock load (up to 5 times the rated torque)

Extremely precise and low-wear, hysteresis loss < 1 arcmin, long service life

Finely graduated sizes, rated torques of 245 Nm to 28,000 Nm

RV-N cycloidal gears are very compact due to the main bearing with an integrated inner race. The reinforcement of the crankshaft bearing achieves very high power density. In addition, all gear components are FEM-optimised and are manufactured using state-of-the-art production processes.

An efficiency ratio of up to 85 %, shock resistance of 5 times the rated torque and extreme precision make the eccentric gears of the RV-N series an outstanding choice for diverse robotic applications. Robots benefit from excellent load conditions due to the reduced weight and lower mass inertia. The RV-N series is also used in medical technology, in machine tools and in positioning applications.

The RV-2800N achieves a rated torque of 28,000 Nm, which makes it the biggest precision gear in the world. A robust and compact design, together with high precision, makes the gear suitable for the most demanding applications. Even entire vehicles can be moved effortlessly with the component sets. The extra large gear is designed for use in applications that require precise positioning of large loads. Such applications include robotics, automotive construction, the glass industry, shipbuilding, mining and cranes. A powerful and efficient alternative to hydraulic applications.

| Model RV- | 25N | 42N | 60N | 80N | 100N | 125N | 160N | 380N | 500N | 700N | 900N | 1500E | 2800N | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Standard ratio | 41 81 107.66 126 137 164.07 | 41 81 105 126 141 164.07 | 41 81 102.17 121 145.61 161 | 41 81 101 129 141 171 | 41 81 102.17 121 141 161 | 41 81 102.17 121 145.61 161 | 41 81 102.81 125.21 156 201 | 75 93 117 139 162 185 | 81 105 123 144 159 192.75 | 105 118 142.44 159 183 203.52 | 137.5 | 65 156 236.29 564 | 274 211 232.72 | |

| Rated torque (Nm) | 245 | 412 | 600 | 784 | 1,000 | 1,225 | 1,600 | 3,724 | 4,900 | 7,000 | 9,000 | 14,700 | 28,000 | |

| Allowable acc. / dec. torque (Nm) | 612 | 1,029 | 1,500 | 1,960 | 2,500 | 3,062 | 4,000 | 9,310 | 12,250 | 17,500 | 22,500 | 36,750 | 70,000 | |

| Emergency stop torque (Nm) | 1,225 | 2,058 | 3,000 | 3,920 | 5,000 | 6,125 | 8,000 | 18,620 | 24,500 | 35,000 | 45,000 | 73,500 | 140,000 | |

| Hysteresis loss (arcmin) | <1.0 | <1.0 | <1.0 | <1.0 | <1.0 | <1.0 | <1.0 | <1.0 | <1.0 | <1.0 | <1.0 | <1.0 | <2.0 | |

| Torsional rigidity (Nm / arcmin) | 61 | 113 | 200 | 212 | 312 | 334 | 490 | 948 | 1,620 | 2,600 | 3,685 | 6,320 | 15,600 | |

| Main bearing capacity | Allowable moment (Nm) | 784 | 1,660 | 2,000 | 2,150 | 2,700 | 3,430 | 4,000 | 7,050 | 11,000 | 15,000 | 12,740 | 44,100 | 62,000 |

| Axial load (N) | 2,610 | 5,220 | 5,880 | 6,530 | 9,000 | 13,000 | 14,700 | 25,000 | 32,000 | 44,000 | 39,200 | 51,000 | 70,400 | |

| Model RV- | 25N | 42N | 60N | 80N | 100N | 125N | 160N | 380N | 500N | 700N | 900N | 1500E | 2800N | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Weight (kg) | 3.8 | 6.3 | 8.9 | 9.3 | 13 | 13.9 | 22.1 | 44 | 57.2 | 102 | 157 | 280 | 544 | |

| A (mm) | 62 | 65.5 | 69.5 | 74 | 80 | 80 | 104 | 131 | 137.5 | 170 | 195.5 | 220 | 270 | |

| B (Ø mm) | 133 | 159 | 183 | 189 | 208 | 221 | 238 | 295 | 325 | 395 | 440 | 570 | 720 | |

| C h7 (Ø mm) | 94 | 118 | 140 | 140 | 160 | 160 | 179 | 222 | 253 | 315 | 335 | 390 | 560 | |

| D (Ø mm) | 113 | 136 | 160 | 160 | 179 | 186 | 202 | 252 | 284 | 350 | 364 | 483 | 633 | |