The precision gears of the new Neco® series have been adapted to the specific needs of customers to set standards for design, efficiency and flexibility. Nabtesco is also revolutionising the process for ordering, configuration and handling of gears.

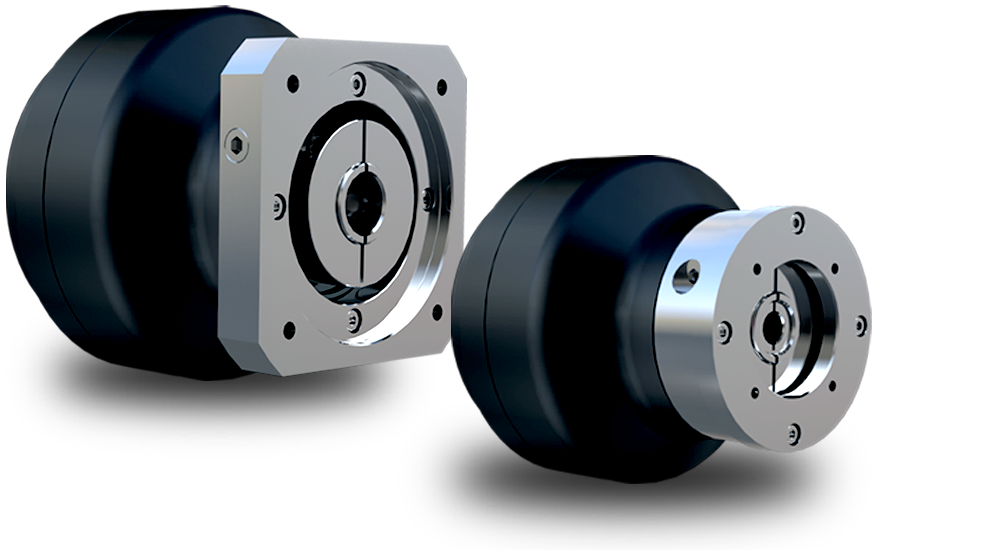

The servo gearboxes are based on the gear units of the RH-N series, featuring a modern clean design, comprehensive corrosion protection, high modularity and maximum flexibility in the motor connection. They achieve high precision with a hysteresis loss of only 0.5 arc.min and are extremely robust, due to dual-bearing eccentric shafts and a bearing-mounted input shaft. That makes Neco® gears especially reliable and durable. Even at high acceleration torques or under high loads they ensure precisely controlled motions and pin-point positioning. Their lightweight design allows the creation of applications with lower inertia, improved load conditions and higher energy efficiency.

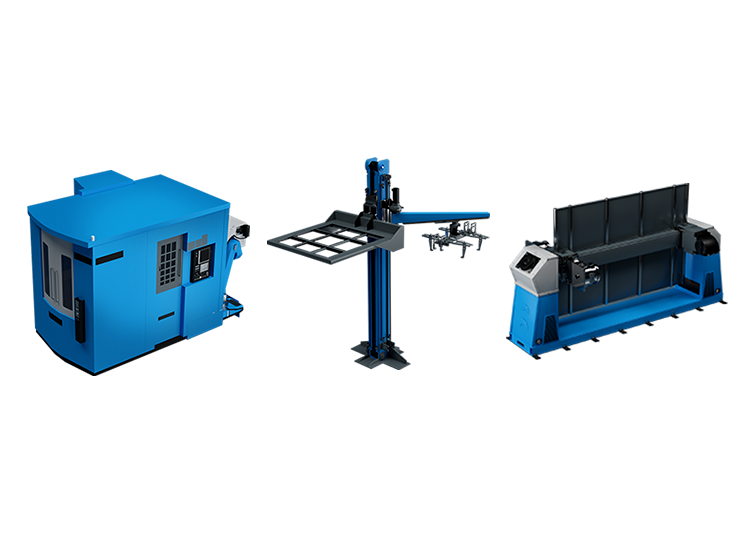

In addition, Neco® gears feature an extremely compact design. The 360-degree animation shows the Neco® in an RD gearbox (blue transparent contour): As one can easily see, it requires much less installation space – and also delivers higher power density.

Innovative gear concept

Modern design, high-performance technology

Intuitive custom gearbox configuration

Contact us now to learn more about the new Neco® series: Use the convenient contact form form or give us a ring.

Why make things more complicated than they need to be? Since not even we have the definitive answer to that question we developed Neco®, a completely new gear concept that makes it as easy as possibly for you to find, configure, install and use the right gears for your application.

Experience gears in a new way– it’s so easy

- Easy to find: New quick finder helps you find the right cycloidal gear faster

- Easy to size: Configure your custom gearbox fast and easy right on our website

- Easy to handle: The QR code on our gears gives you direct access to manual videos, operating manuals and live support

|

|

|

|

|

|

|

|

|

|

High-torque gears for heavy loads

For large loads and high forces Nabtesco has now expanded the successful Neco® series to include sizes for heavy-duty applications. The high-torque gears are characterised by extreme precision, maximum robustness and a compact design, and can easily handle the heaviest loads. A high level of modularity and standardisation allows economical series production and guarantees high availability. That is unique in the area of large precision gears.

Numerous advantages for your automation:

Neco®HT closes the gap between robotics and industrial gears

Heavy loads are often moved by means of hydraulic systems or large planetary gears. However, cycloidal gears are clearly superior in most cases. Their special design principle achieves very high reduction ratios with only two to three gear stages, which guarantees precise positioning in a very compact design.

The motor shaft is adapted by means of a radial clamping ring with a low-inertia design. The ring reduces inertia on the motor shaft by up to 39% to enable extremely dynamic cycles. This gives the user advantages such as shorter cycle times, as well as increased productivity and efficiency. Mounting of the motor is likewise simplified greatly since no alignment of the drive pinion is necessary. A flexible system with modular bushings and flanges guarantees uncomplicated adaptation for use with all standard servomotors.

In addition to design innovations, another advantage of Neco® gears is their advanced corrosion protection. SSA coating (a special corrosion protection method by Nabtesco) is combined with oxidation to provide optimal protection. The result is comprehensive corrosion protection – including the gear output shaft and the running surfaces for the radial shaft seals.

Their high dynamics, positioning accuracy and rotational speed precision make these compact cycloidal gears ideal for highly dynamic servo applications. In addition, the smooth surfaces and comprehensive corrosion protection ensure reliable operation even in demanding conditions, and comply with the stringent hygiene standards of the food and packaging industry.