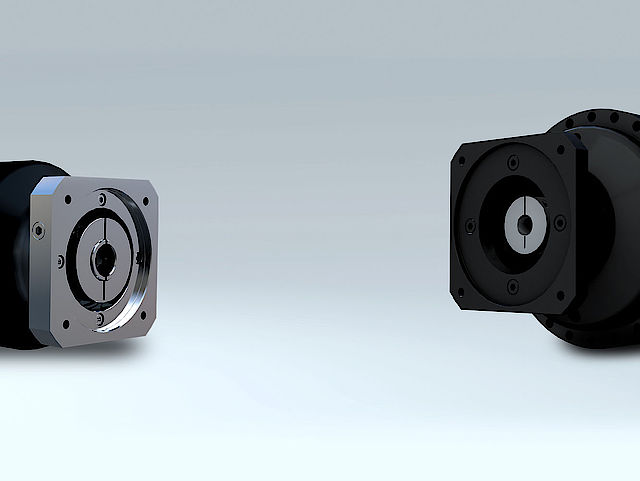

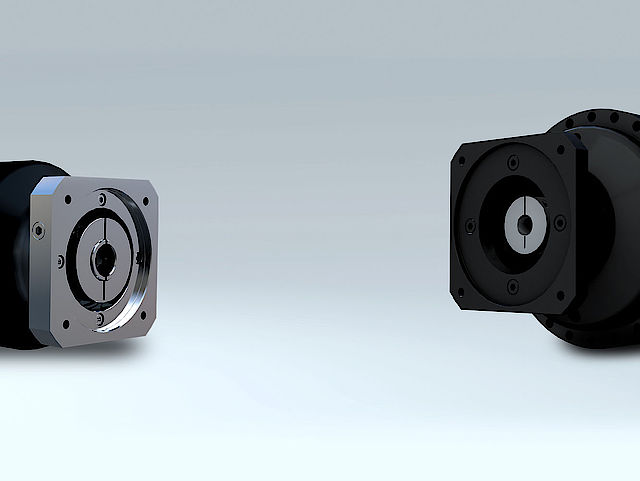

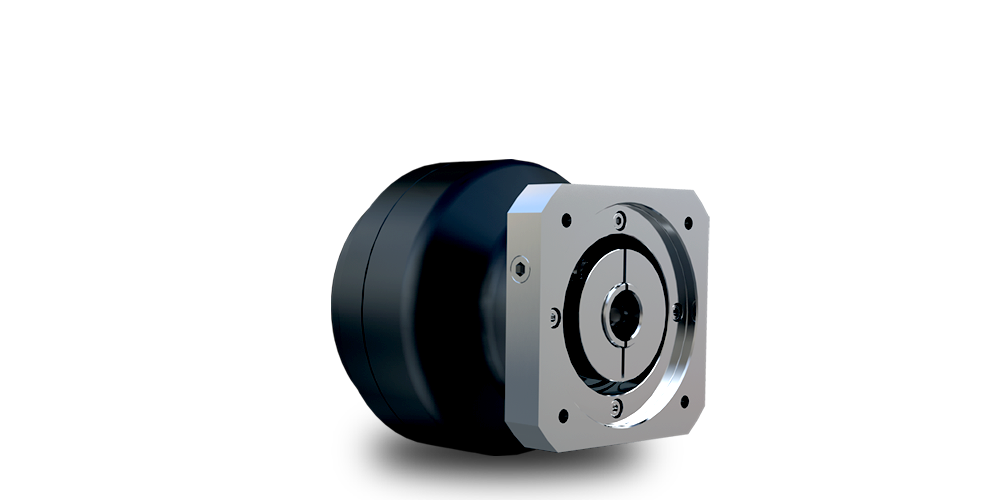

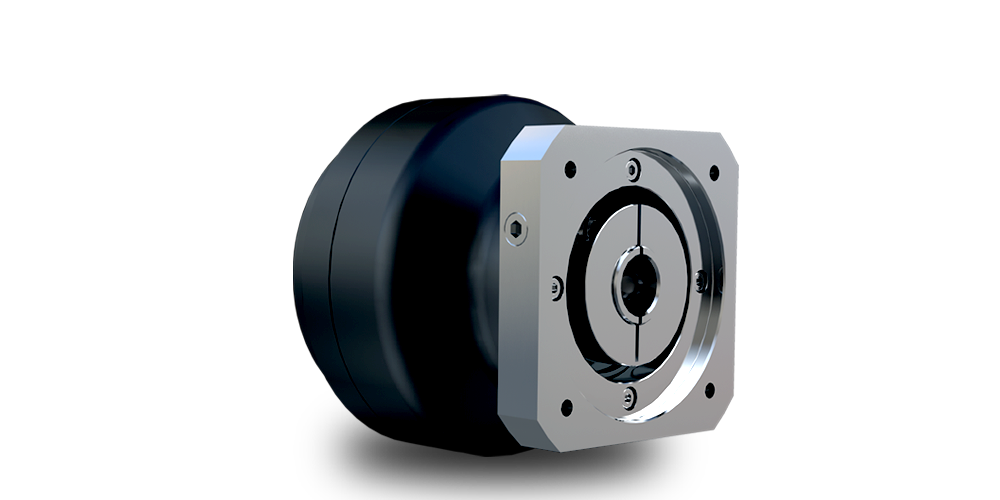

The servo gearboxes of the new Neco® series feature high power density, extremely effective corrosion protection, and maximum flexibility in the motor connection – all in an elegant and compact design. Furthermore, we have developed a modular system that allows the customer to configure a custom gearbox quickly and easily.

High modularity for maximum flexibility

Ready to install and user-friendly

Blackbox concept minimises risks

With the Neco® series we have created a modern and economical gear solution that fulfils the most stringent requirements for performance and user friendliness. The modular design features comprehensive corrosion protection with a low-inertia clamping ring for an enormous boost in performance and a broad application spectrum. Assembly of the motor is likewise reduced greatly since no alignment of the drive pinion is necessary. Neco® gears can be adapted for use with all standard servomotors, ensuring fast installation and assembly. The intuitive way to find the right gearbox: The introduction of Neco® is accompanied by a newly developed gear concept that makes it very easy to find, configure, install and use the gears. Ordering and handling of our gears has never been so easy!

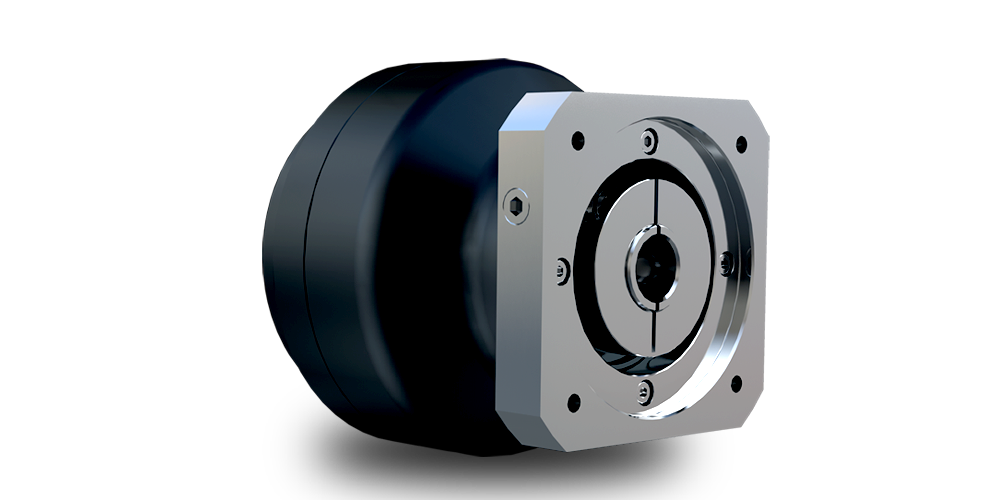

For large loads and high forces Nabtesco has now expanded the successful Neco® series to include sizes for heavy-duty applications. The high-torque gears are characterised by extreme precision, maximum robustness and a compact design, and can easily handle the heaviest loads. A high level of modularity and standardisation allows economical series production and guarantees high availability. That is unique in the area of large precision gears.

Model Neco® | 25 | 42 | 80 | 125 | 160 | |||

|---|---|---|---|---|---|---|---|---|

| Standard reduction ratio | 41 | 41 | 41 | 41 | 41

| |||

Rated torque (Nm) | 245 | 412 | 784 | 1,225 | 1,600 | |||

Max. acceleration/deceleration torque (Nm) | 612 | 1,029 | 1,960 | 3,062 | 4,000 | |||

Emergency stop torque (Nm) | 1,225 | 2,058 | 3,920 | 6,125 | 8,000 | |||

Hysteresis loss (arcmin) | <0.5 | <0.5 | <0.5 | <0.5 | <0.5 | |||

Torsional rigidity (Nm/arcmin) | 61 | 113 | 212 | 334 | 490 | |||

Capacity of the bearings | Axial load (N) | 784 | 1,660 | 1,190 | 3,430 | 2,050 | ||

Max. allowable moment (Nm) | 2,610 | 5,220 | 6,530 | 13,000 | 14,700 | |||

Model Neco®HT - | 380 | 500 | 700 | 900 | |||

|---|---|---|---|---|---|---|---|

| Standard reduction ratio | 75 | 81 | 105 | 137.5 | |||

Rated torque (Nm) | 3,724 | 4,900 | 7,000 | 9,000 | |||

Max. acceleration/deceleration torque (Nm) | 9,310 | 12,250 | 17,500 | 22,500 | |||

Emergency stop torque (Nm) | 18,620 | 24,500 | 35,000 | 45,000 | |||

Hysteresis loss (arcmin) | <0.5 | <0.5 | <0,5 | <0,5 | |||

Torsional rigidity (Nm/arcmin) | 948 | 1,620 | 2,600 | 3,685 | |||

Capacity of the bearings | Axial load (N) | 7,050 | 11,000 | 15,000 | 12,740 | ||

Max. allowable moment (Nm) | 25,000 | 32,000 | 44,000 | 39,200 | |||