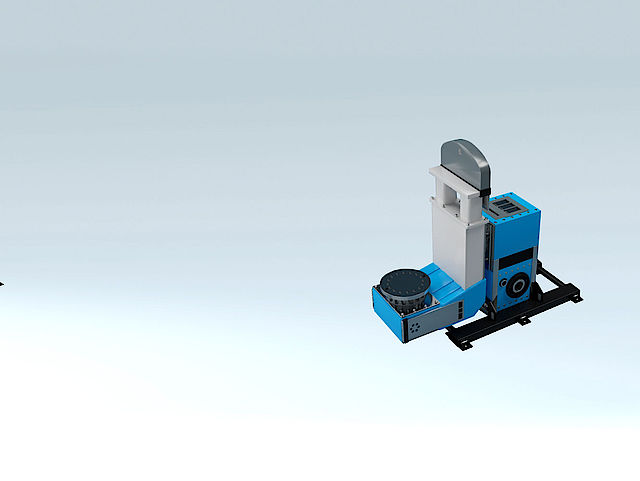

Robotic welding systems have to operate with high speed and absolute precision. Positioners and rotary indexers provide for exact alignment of the workpieces. In welding positioners, a precision gear drives the horizontal rotary axis. This makes it possible to weld all spots along this axis – even complex geometrical structures – within a tolerance of tenths of millimetres, without having to reclamp the workpiece. The weld puddle must be kept exactly in the tray. Nabtesco cycloidal gears are designed for such applications.

Our cycloidal gears enable the fast acceleration and braking of welding positioners.

Welding robots require maximum precision. Nabtesco gears provide the necessary “sensitivity” in this application.

The low wear ensures a long service life and provides for smooth operation throughout the entire life cycle.

Our robotic gears feature a very compact design that can nevertheless withstand high shock loads.

Our cycloidal gears operate with absolute precision and reliability. They prevent even minimal deviations to eliminate faulty weld points. The robust and ultra-precise gears of the Nabtesco RV-C- and RD-C series feature a compact design, high shock loads and low backlash. In addition, the hollow shaft of the RV-C and RD-C gears provides an elegant solution for the space-saving feed-through of cables and supply lines.