Read more of the latest news from Nabtesco. Discover our company news, specialist articles, press releases and LinkedIn Posts.

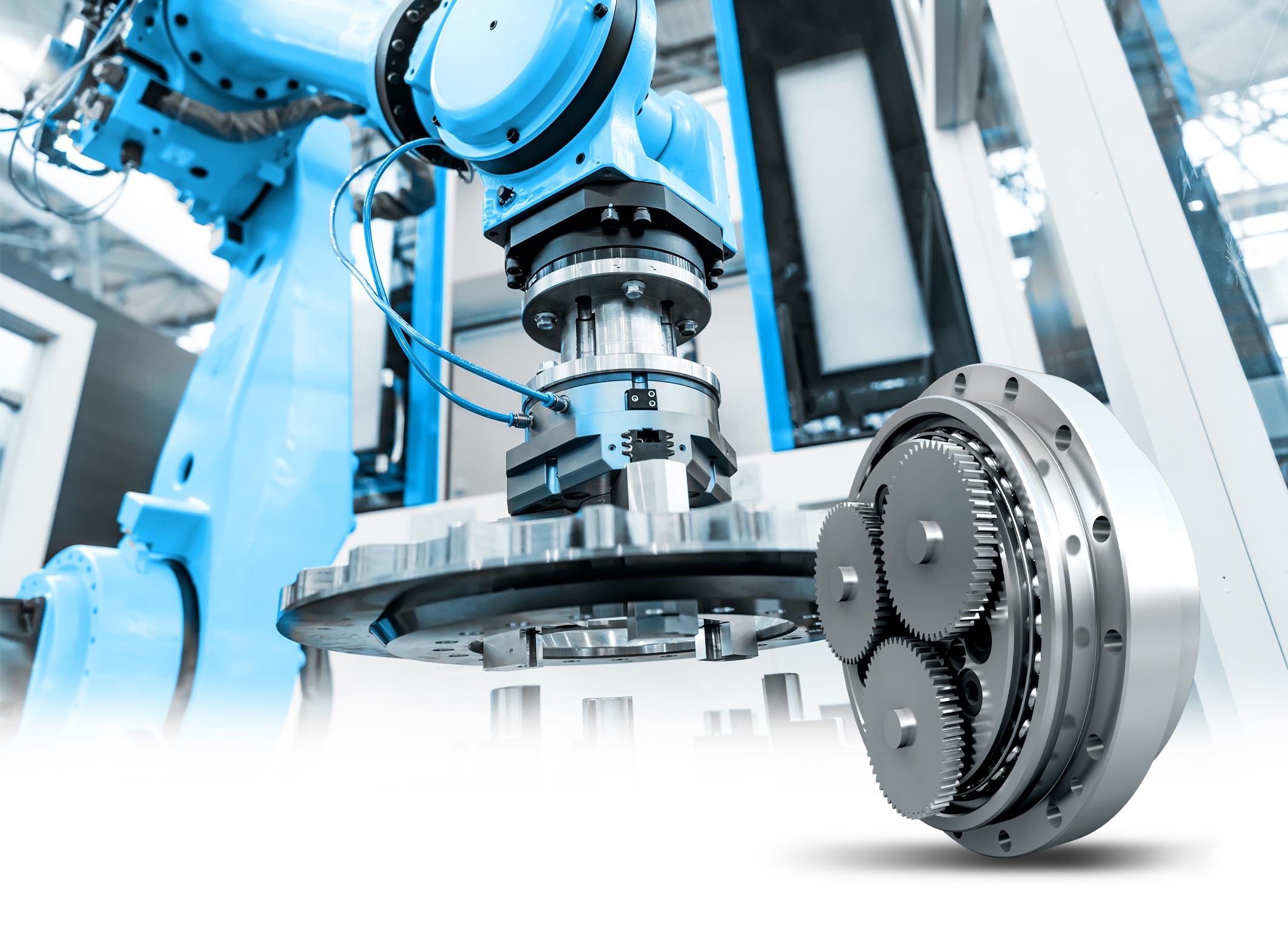

For use in heavy-duty robots Nabtesco, the largest manufacturer of cycloidal gears and Number 1 in robotics, offers an extensive range of products for high-performance gear systems with torque ratings of up to 28,000 Nm. The heavy-duty gears are characterised by extreme precision, maximum robustness and a compact design, and can easily handle the heaviest loads.

High torque capacity combined with minimal backlash and a compact design

In cycloidal gears, power transmission is achieved by cams and rollers. This design ensures continuous contact and even distribution of forces within the gearbox, which produces high rigidity. As a result, it is possible to transmit very high torques with maximum precision (hysteresis loss < 1 arc.min). The increase in backlash remains negligible throughout the entire life cycle. Furthermore, their special design achieves excellent behaviour with respect to dynamics, load capacity and compactness. Even high reduction ratios can be achieved with only two or three gear stages. The integrated main bearings absorb both axial and radial loads and bending moments, and provide for high moment rigidity and resistance to shock loads (up to 500 % of the rated torque).

Incidentally: The integrated main bearings allow Nabtesco gears to withstand 250 % higher bending moments than conventional planetary gears of a comparable size. This eliminates the need for additional external bearings, which allows a more compact robot design with maximum precision, dynamics, load capacity and rigidity.

The world’s largest precision gearbox

With a torque rating of 28,000 Nm the RV-2800N is currently the largest and most robust precision gearbox in the world. The XXL gearbox features an optimal combination of performance, torsional rigidity and compactness, which opens up entirely new applications for robots that in the past were possible only with hydraulic or spindle solutions. This is the case, for example, when moving large panes of glass, sheet steel, machine components or even entire motor vehicles. In such applications, heavy-duty robots also benefit from good load conditions as a result of the reduced weight and lower inertia.

Nabtesco cycloidal gears: An ideal solution for heavy-duty robotics

Whether for the automotive sector, steel industry, sheet metal handling, metalworking or aircraft construction: In all applications requiring exact robot-based positioning of heavy and large components, high-torque gears from Nabtesco are in demand. The robust precision gears, which are available with a solid or hollow shaft, guarantee safe handling and pin-point positioning – in combination with maximum reliability and a long life.