Read more of the latest news from Nabtesco. Discover our company news, specialist articles, press releases and LinkedIn Posts.

Hardly any other field has such stringent safety requirements as medical technology. Because if only one component does not function perfectly, the consequences can be far-reaching in some circumstances. To prevent harm to both patients and personnel, all mechanical components and assemblies must be designed with a sufficient safety margin, in addition to complying with numerous regulatory standards, regulations and directives – and proving this compliance in extensive tests and operating scenarios before being put into use. This also applies in particular to gears.

Safe gears are the top priority in medical technology

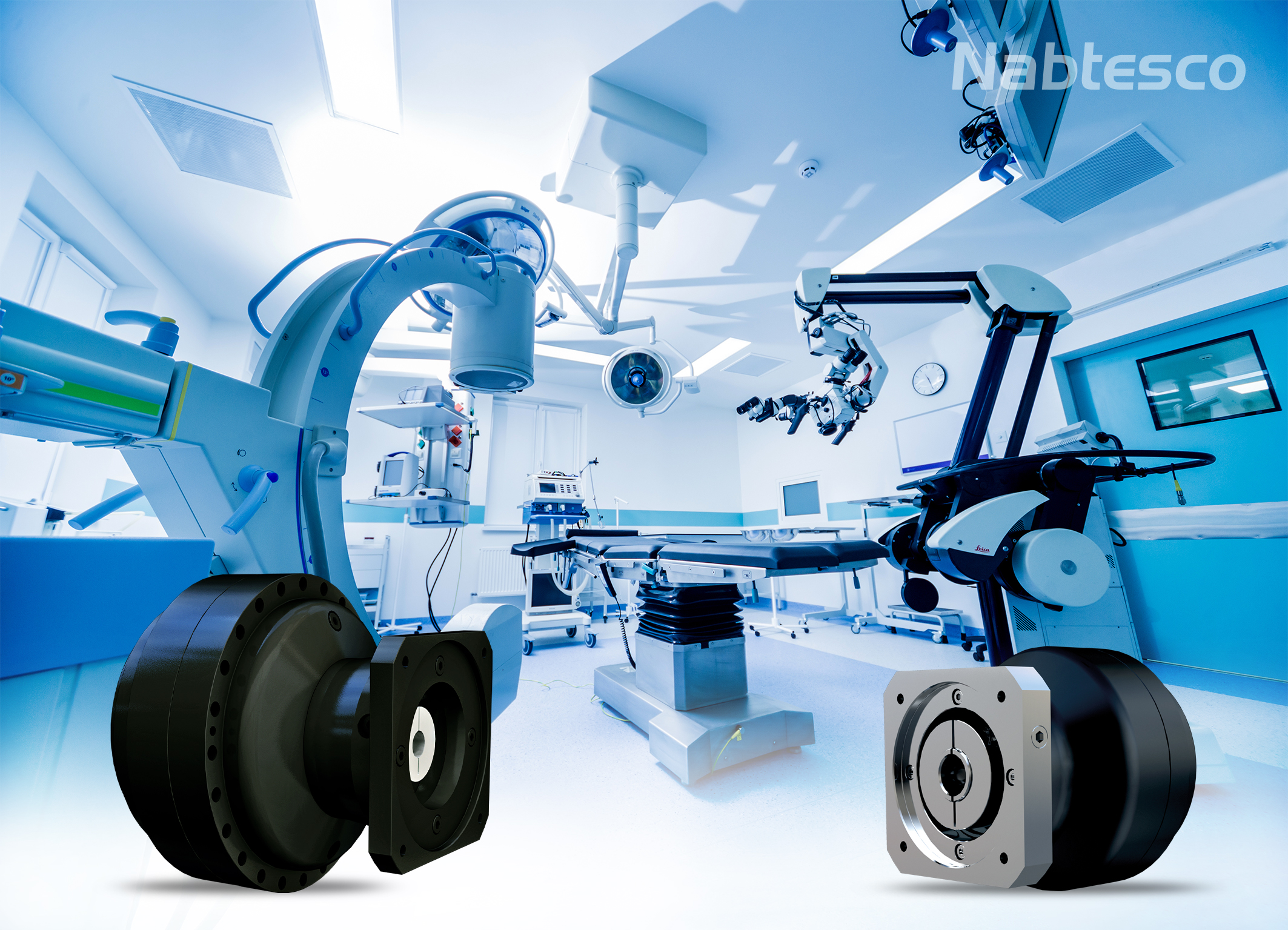

As a central drive technology component, gears provide the necessary motion in medical instruments, for example for high-precision positioning of X-ray and ultrasound scanners, examination tables, surgical robots, OP tables or hospital beds. In applications such as lab automation and robot-assisted rehabilitation, gears are also an important factor for increasing the quality of patient care. That is because of their special function: Gears convert torques, rotational frequencies and directions, as well as forces, which makes them crucial for the precision, safety and reliability of medical technology products. Minimisation of errors, improved diagnostic behaviour, optimized treatment and therapy methods, as well as more patient comfort are important objectives in this regard.

Precision cycloidal gears offer decisive benefits

Cycloidal gears fulfil the stringent safety standards required in medical technology with no compromises. They achieve high-precision positioning down to hundredths of a millimetre, guarantee a large safety margin and feature a hygiene-friendly design, as well as constant operating behaviour and low-noise operation. The extra safety of the gears is achieved primarily by the offset arrangement of the cams. This arrangement ensures full engagement of the cams via the pins. Even torque distribution us achieved within the gearbox, while the power flow is simultaneously transmitted outward into the housing material. Consequently, cycloidal gears are very rigid and able to withstand high overloads. Other features include double-bearing eccentric shafts and a bearing-mounted drive shaft. Integrated angular ball bearings, which absorb both axial and radial loads and bending moments, provide for high moment rigidity and resistance to impacts and overloads. As a result, cycloidal gears allow peak loads of up to 500 % of the rated torque in emergency stop situations, therefore providing the best possible protection for patients and operating personnel in the event of a malfunction. An emergency stop torque of up to 800 % of the rated torque can also be implemented. This is made possible by setting up specific test scenarios and through close cooperation with universities, technical colleges and research institutes. Nabtesco is therefore capable of implementing exceptional requirements for the field of medical technology.

Cycloidal gears for medical technology

Especially the gears of the Neco® and Neco®HT series – which feature high power density, user-friendliness, and a clean, closed design – are ideal for use in medical technology and the health sector. They guarantee precisely executed motions, pin-point positioning, maximum safety and efficient cleaning. Hollow shaft gears of the RD-C series are ideal for building encapsulated systems. The precision gears feature a large hollow shaft that can accommodate cables, hoses and supply lines in a hygienic and safe-spacing design.

Medical technology: Cycloidal gears provide extra safety

• High safety margin: Emergency stop torque of up to 500 % of the rated torque (optionally up to 800 %)

• Extreme precision: Hysteresis loss of 0.5 to max. 1 arc.min throughout the entire service life

• Resistance to cracking and breakage

• Maximum reliability: Low-wear design for a long life, virtually maintenance-free

• Constant operating behaviour

• Hygiene-friendly design

• Hollow shaft gears for building encapsulated systems

• Fulfilment of all safety regulations, standards and test specifications

• 100 % tested

• Verification by independent institutes and labs

• Implementation of specific test scenarios for individual requirements

Would you like to learn more about the specific benefits of cycloidal gears? Click here!